Typical Obstacles in Welding Inspection Madison and How to Overcome Them

Typical Obstacles in Welding Inspection Madison and How to Overcome Them

Blog Article

Understanding the Basics of Welding Assessment to Guarantee High Quality and Security

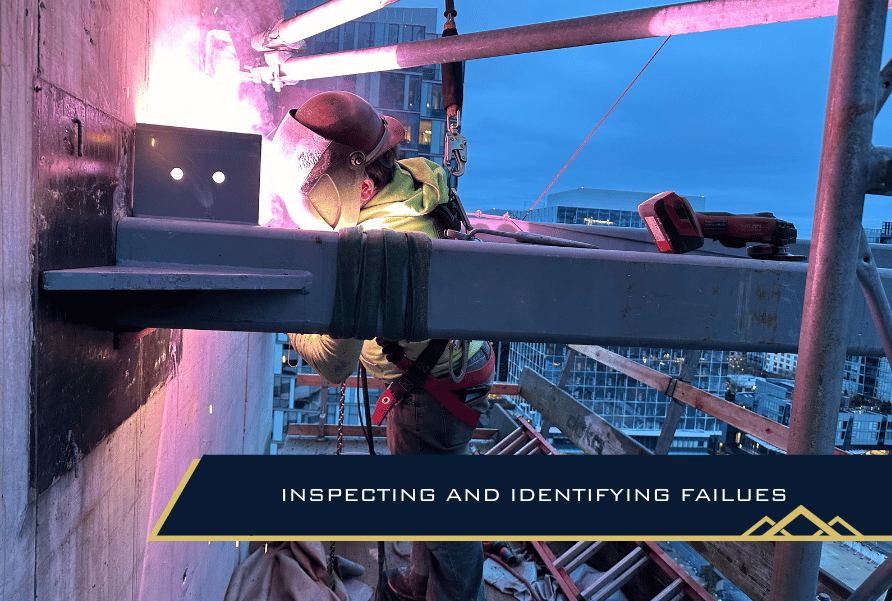

In the world of contemporary engineering, welding assessment stands as a cornerstone for ensuring both the quality and safety and security of structural productions. The process entails a careful analysis of bonded joints, employing innovative strategies such as radiographic and ultrasonic screening to discover concealed flaws. The competence of certified assessors is essential, as they connect the void between theoretical standards and functional application. Their duty expands beyond mere discovery, including the documents and communication of searchings for to appropriate stakeholders. Yet, what are the subtleties of these examination approaches that make them vital for preserving architectural stability?

Importance of Welding Evaluation

In the world of industrial construction, the significance of welding evaluation can not be overemphasized. Welding assessment plays a critical duty in ensuring the honesty, safety, and longevity of bonded structures (Welding Inspection Madison).

The procedure of welding naturally entails complicated variables, consisting of temperature, product residential or commercial properties, and ecological problems, all of which can affect the high quality of the weld. An extensive assessment determines defects such as splits, porosity, and insufficient combination, which can endanger the toughness and dependability of the weld. By detecting these issues early, rehabilitative activities can be taken, consequently lowering the threat of failure and linked expenses.

Furthermore, welding assessment adds to regulatory compliance, as several industries are controlled by strict safety and security criteria and guidelines. Failure to adhere to these guidelines can cause legal responsibilities and financial penalties. Inevitably, welding examination not only safeguards physical structures however likewise safeguards human lives and maintains sector track records.

Key Welding Evaluation Approaches

Although welding assessment is critical to making certain the high quality and safety of bonded structures, it is the specific techniques employed that identify the efficiency of the evaluation process. Key welding evaluation methods can be extensively classified into non-destructive testing (NDT) and damaging screening. Non-destructive testing methods such as aesthetic evaluation, ultrasonic screening, radiographic screening, magnetic particle testing, and liquid penetrant testing are mainly utilized to evaluate the residential properties of a weld without causing damage. Aesthetic assessment is often the initial action, including a comprehensive examination of the weld's surface area for defects like cracks or porosity.

Magnetic particle testing and fluid penetrant screening are surface examination approaches used to find surface and near-surface imperfections. These comprehensive assessment approaches guarantee that welds fulfill market requirements and safety demands, thus ensuring structural stability and efficiency.

Role of Licensed Inspectors

Certified examiners play a pivotal role in the welding inspection process, making certain that all welds conform with strict market requirements and security guidelines. Their expertise is necessary in determining issues or irregularities that may compromise the structural stability of a weld. By meticulously analyzing each weld, accredited assessors aid prevent potential failings that could result in pricey repair work or harmful mishaps.

To come to be qualified, assessors must go through strenuous training and screening, which familiarizes them with various welding techniques, products, and testing methods. This comprehensive knowledge permits them to assess weld high quality properly and make notified judgments about their safety and security and reliability. Qualified inspectors are skilled in interpreting requirements and blueprints, making certain that the welding work lines up with the task's design requirements.

An integral component of their function is to record their findings completely, offering a comprehensive document of the assessment procedure. Their contribution is important in maintaining high degrees of quality and safety in welding procedures.

Tools Made Use Of in Welding Examination

Welding examiners rely upon a variety of specialized devices to execute their tasks properly, making sure each weld satisfies the required requirements. Amongst these devices, visual assessment help like amplifying glasses and mirrors are basic, allowing examiners to closely take a look at welds for surface flaws such as cracks, redirected here porosity, and undercut. Calipers and fillet weld assesses are vital for measuring weld dimensions to see verify conformity with layout specs.

Advanced tools prolong beyond visual aids, including non-destructive screening (NDT) equipment. Ultrasonic screening tools are pivotal in discovering subsurface flaws, making use of acoustic waves to reveal interior interruptions without jeopardizing the weld's integrity. Radiographic testing utilizes X-rays or gamma rays to capture photos of a weld's interior, highlighting possible issues.

Magnetic fragment testing is an additional vital device, particularly for detecting surface and near-surface interruptions in ferromagnetic products. By applying ferrous particles and magnetic fields, assessors can determine imperfections that may otherwise be unseen.

Dye penetrant assessment is usually used for non-ferrous materials, offering a contrast-enhanced visual look for surface-breaking issues. Welding Inspection Madison. With each other, these devices enable welding assessors to adequately assess weld top quality, guaranteeing safety and security and dependability in numerous applications throughout markets

Guaranteeing Structural Stability

Welding procedures need to follow recognized criteria and codes, such as those defined by the American Welding Culture (AWS) or the International Organization for Standardization (ISO) These standards ensure that the welds can hold up against ecological elements and functional anxieties. Qualified and licensed welders play a vital role in this process, as their expertise ensures that check over here strategies are applied properly, minimizing flaws such as splits, porosity, and insufficient combination.

Post-weld examination is an additional necessary part of verifying architectural stability. Non-destructive testing (NDT) methods, including ultrasonic testing and radiographic screening, are employed to discover subsurface defects without jeopardizing the bonded structure. These evaluations confirm that the welds fulfill the required quality standards, offering guarantee of their longevity and dependability. Inevitably, ensuring architectural integrity in welding not just safeguards human lives but also secures financial investments and boosts the durability of crafted structures.

Final Thought

The fundamentals of welding examination are necessary for maintaining the quality and safety and security of welded frameworks. The usage of specialized tools even more boosts the assessment procedure, inevitably protecting human lives and lengthening the life-span of bonded buildings.

Welding evaluation plays a critical role in ensuring the integrity, safety, and durability of bonded structures.Although welding examination is crucial to ensuring the quality and safety of bonded structures, it is the particular techniques employed that determine the performance of the inspection procedure. Key welding evaluation methods can be extensively classified into non-destructive screening (NDT) and harmful screening.Certified assessors play a crucial duty in the welding examination procedure, guaranteeing that all welds conform with rigorous sector criteria and safety and security laws.The fundamentals of welding assessment are important for maintaining the top quality and safety of bonded frameworks.

Report this page